en

en

Stopping The Rot

by Peter Gumbrell, 2001-03-22

I part-exchanged my first, B registration R4 for this slightly later GTL edition from 1986. (That isn't me in the picture above, by the way, but rather a friend of the former owner). Here in the outskirts of Manchester, a city with a reputation for its rain, it is often difficult to maintain older cars because of the rust and rot these climes bring about. Renault 4s in particular have common problems with this, due to some elements of their design and materials. Had my old car not been trashed (by some Salfordian scallies a few months earlier), it would still have been unroadworthy anyway, as the bottom was falling off. The same thing happened to the first Four my sister had owned a few years previous. The R4's underside, rear axle and chassis legs are notoriously prone to rotting away, and addressing this is near impossible without spending huge amounts of money. Some garages might perform a cheaper fix, such as putting a bar across to give the axle something to hold onto, but this is usually a short term measure which won't secure the problem for long.

Unfortunately if, like me, you're not a dab hand at welding and restoration, you've either got to be lucky and know someone crazy enough to do the work for you cheaply, or have it done 'professionally' and face an enormous bill, and even then the quality is not always reliable. Fortunately, the previous owner of this car had gone to ridiculous lengths to prevent any more deterioration in the hope of keeping the car himself, but after a change of circumstances he decided to sell and I happened to be interested in a new R4 at the time. He spent much of summer 1999 doing the work seen here, and practically made himself sick from the level of effort.

These sections under the bonnet are another area of concern for many R4 owners. Here you can see how the front inner wing panels were straightened up, primed with red lead primer, after which they were finished with further coats of protection and repainted.

Miaow.

Now to some serious work.

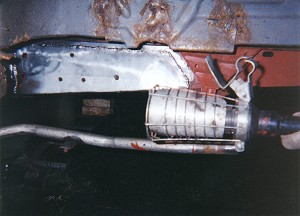

The first in this next series of snaps shows one of the areas of corrosion on the underside. The rear chassis has been completely stripped down, with the rear axle and fuel tank removed in order to carry out the repairs.

All the rot was completely cut out, then the affected metal was replaced with brand new class A zinc galvanised steel. This sort of treatment is not what you would expect to receive at a garage, which will instead usually perform a bodge job to get a car through the next test. Typically, they will just fix a steel plate over the affected area, but this serves only to make the problem worse, by creating a water trap which quickly erodes all the surrounding metal, and you could find the entire back chassis rotted away within a short space of time. Once the corrosion reaches the rear suspension mounting points, they begin to move when driving, causing banging when driving over bumps, etc. By this stage you'll have difficulties saving the car from the scrap heap.

Government Warning: Going to these extremes could seriously damage your health!

You can see above the final effect of replacing the bad metal on one side. Below are some shots of a similar repair on the other side.

As if that wasn't enough, the chassis and underside were shot blasted, red lead oxide primed, enamel painted, undersealed with Finnegan's Underseal, then the entire car body was injected with Waxoyl rust prevention.

The rear axle was removed and shot blasted before being primed with six coats of red lead primer, and finally finished with four coats of Hammerite.

Various other jobs were done on the car after this, including a full conversion to unleaded fuel. Even the fuel tank was painted green! As the number of R4s becomes more scarce, it'll be difficult for those people living in wet countries to find models in good condition with no rot. One option may be to go abroad and import one from a drier country, and inevitably many cars will be stripped down, with the best bits being combined to make one good model. I guess what we all want is for Renault to continue manufacture of the R4, or at least guarantee the supply of new parts for many years to come. After all, a car that's sold over 8 million surely deserves to make it to 50 years of age.

home |

articles |